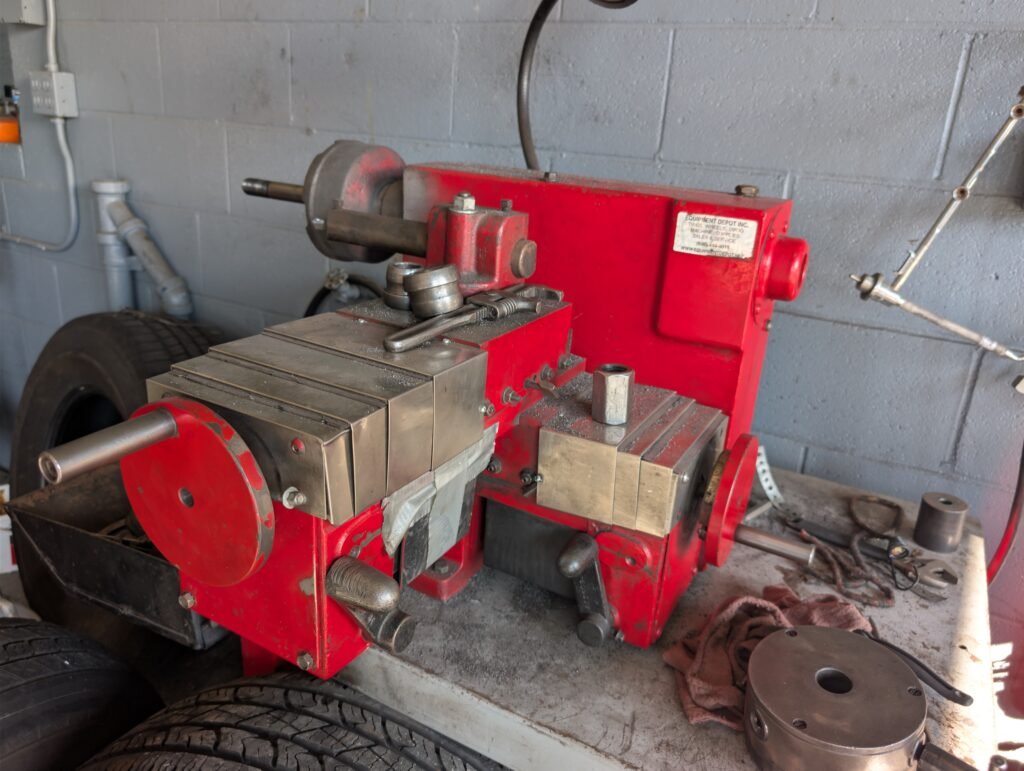

Accuturn Brake Lathe Repair

Accuturn Brake Lathe Service and Repair

We provide complete Accuturn brake lathe service, diagnostics, repair, calibration and parts replacement for all Accuturn brake lathe models. Whether your machine is producing vibration, uneven cuts, excessive noise, or poor machining accuracy, our technicians restore full operational performance.

Our service covers all Accuturn brake lathes, Accu-Turn units and rotor brake lathes used for resurfacing brake rotors and drums, including brake disk lathes, disk brake lathes, on-car brake lathe systems and brake rotors machining equipment.

Professional Accuturn Brake Lathe Diagnostics and Repair

Accuturn brake lathes are designed to deliver stable, accurate, and consistent resurfacing. Over time, mechanical components wear and alignment drifts, affecting cut quality. Our full diagnostic process identifies and resolves all performance issues.

Mechanical and Structural Inspection

We inspect spindle bearings, crossfeed assemblies, arbor fitment, gear mechanisms, motors, switches, pulleys, adapters, tool posts and electrical components. Any worn or damaged elements are repaired or replaced.

Calibration and Machining Accuracy

We correct spindle runout, align the cutting head, adjust feed rates and set proper cutting depth to achieve clean and consistent surfaces on rotors and drums. Every unit is test-cut to ensure accuracy.

Vibration, Chatter and Noise Correction

Brake lathes must operate smoothly to produce an even finish. We address issues caused by bearings, adapters, misalignment, worn feedscrews or unstable fixtures to eliminate chatter and vibration.

Electrical and Motor Repair

We troubleshoot switches, wiring, direction changes, rotation inconsistencies and torque issues. Motor replacements and electrical repairs are performed as needed.

Accuturn Brake Lathe Models We Service

We work on the full Accuturn Corp and Accuturn Manufacturing Inc lineup, including:

- Accuturn 7700 Series

- Accuturn 8800 Series

- Accuturn 8900 Series

- Accuturn 8911 / 8912

- Accu-Turn bench brake lathes

- Accuturn rotor brake lathes

- Accuturn disc and drum brake lathes

- On-car brake lathe systems

Any Accuturn or Accu-Turn variation can be serviced, rebuilt or calibrated.

Technical Performance of Accuturn Bench Brake Lathes

Accuturn bench brake lathes rely on balanced spindle support, rigid construction and a smooth crossfeed system to maintain accurate machining. Precise cutting torque, uniform feed control and minimal vibration are essential for quality rotor and drum resurfacing.

We evaluate and restore critical specifications including:

- spindle runout and bearing condition

- arbor alignment and adapter seating

- crossfeed stability and cutting head positioning

- gear engagement and feed screw wear

- motor balance, torque output and switching performance

- vibration control and harmonic behavior

- cutting geometry and surface finish quality

Restoring these specifications ensures your Accuturn brake lathe performs at the accuracy level expected from factory standards.

Why Accuturn Specifications Matter

If tolerance, alignment or surface accuracy fall outside Accuturn design parameters, machining issues may appear:

- spiral or wavy cuts

- chatter marks

- excessive rotor heat

- inconsistent surface finish

- vibration marks or tool chatter

- difficulty maintaining cutting depth

Our calibration process resets the machine to optimal machining conditions, ensuring every cut maintains proper feed rate, tool engagement and spindle rotation.

Accuturn Brake Lathe Parts and Component Replacement

We source and install compatible parts for Accuturn brake lathes, including:

- motors

- switches

- crossfeed components

- spindle bearings

- cutter tools

- adapters, arbors and tooling kits

- pulleys and belts

- electrical components

Correct parts selection is essential for restoring machining accuracy and prolonging machine life.

Rotor and Drum Brake Lathe Service

In addition to Accuturn-specific systems, we service:

- brake rotor lathes

- rotor brake lathe equipment

- brake disk lathes

- disk brake lathe systems

- on-car brake lathes

- brake rotors machining equipment

We eliminate vibration, chatter marks, uneven finishes and feed errors.