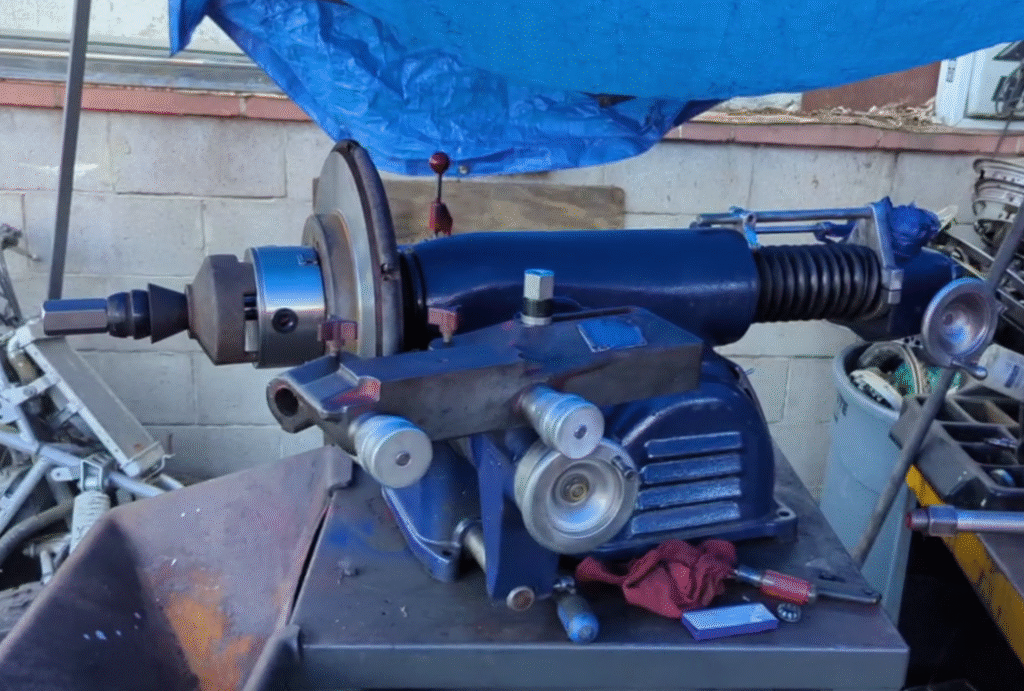

Ammco 4000 Lathe Service & Repair

Ammco 4000 and 4000B-SP Brake Lathe Service and Repair

We provide complete service, repair, calibration and parts replacement for the Ammco 4000, Ammco 4000SP and Model 4000B-SP Single Pass Disc/Drum brake lathes. These machines are known for durability and precision, but after years of shop use, components begin to wear, alignment shifts, and machining accuracy declines. Our technicians specialize in restoring Ammco 4000 and 4000B-SP performance to factory-level specifications.

Whether you are searching for Ammco 4000 brake lathe service, Ammco brake lathe 4000 repair, or support for the 4000B-SP single pass disc/drum lathe, we deliver on-site diagnostics and professional repair for all configurations of these models.

Complete Ammco 4000 Brake Lathe Diagnostics

The Ammco 4000 is built for accurate rotor and drum machining. Over time, vibration, runout, worn bearings and feed issues affect cut quality. We inspect all critical systems, including:

- spindle bearings and housing

- arbor runout and adapter seating

- crossfeed assembly and depth control

- motor torque and rotation consistency

- feed screw backlash and wear

- cutter head integrity and alignment

- vibration and harmonic transfer

- electrical components, switches and wiring

After testing, we calibrate the machine according to Ammco machining tolerances.

Ammco 4000 Calibration and Performance Restoration

A fully calibrated Ammco 4000 produces clean, smooth rotor surfaces and accurate drum cuts. We correct:

- spindle alignment

- arbor runout

- tool positioning

- feed rate accuracy

- crossfeed consistency

- depth-of-cut precision

A live test cut confirms machining accuracy before returning the machine to service.

Ammco 4000 Brake Lathe Specifications

Below are the technical capacities supported during service and calibration.

Ammco 4000 – Technical Specifications

| Specification | Value |

|---|---|

| Max Rotor Diameter | 14.5″ (17.5″ with optional accessories) |

| Max Rotor Face Width | 3.75″ |

| Max Rotor Thickness | 1.875″ |

| Max Arbor Capacity | A. 100 lbs (Standard) B. 200 lbs (Heavy Duty – optional) C. Outboard (optional) |

| Spindle Speed | 100, 200 RPM |

| Drum Feed Rate | 0.002″ – 0.020″/REV |

| Rotor Feed Rate | 0.002″ / 0.010″ per REV |

| Max Drum Depth | Up to 6.875″ |

| Shipping Weight | 365 lbs |

Ammco 4000B-SP Single Pass Specifications

This model is designed for efficient single-pass cutting with consistent surface finish.

Ammco 4000B-SP – Technical Specifications

| Specification | Value |

|---|---|

| Maximum Rotor Diameter | 14.5″ |

| Maximum Rotor Thickness | 1.875″ |

| Brake Drum Diameter | Minimum 6″ – Maximum 28″ |

| Maximum Drum Depth | 6.875″ |

| Spindle Travel | 6.875″ |

| Spindle Speed | 100 RPM |

| Spindle Feed Speed (Drum) | 0.005 in/rev |

| Cross Feed Speed (Rotor) | 0.002 in/rev |

| Maximum Load | Standard 1″ Arbor – 100 lbs |

| Rotor Feed Rate | 0.002″ / 0.010″ per REV |

| Floor Space Requirements | 48″ width × 34.5″ depth |

| Electrical Requirements | 115v AC, 20A @ 60 Hz, 1 Phase |

| Shipping Weight | 365 lbs |

Common Ammco 4000 and 4000B-SP Issues We Repair

- vibration or chatter

- uneven rotor finishes

- spindle bearing noise

- feed movement issues

- gear slipping or noise

- motor overheating or rotation faults

- depth-of-cut inaccuracy

- tool holder instability

- arbor or adapter imbalance

We resolve these issues on-site and perform a full calibration after repairs.

Parts Replacement for Ammco 4000 and 4000B-SP

We supply and install:

- spindle bearings

- motors and pulleys

- switches and wiring

- feed screws and gears

- cutter tools and holders

- arbors and adapters

- belts and drive components

Correct parts selection ensures accuracy, safety and long-term reliability.

Why Choose Our Ammco 4000 Service

- Specialized technicians for Ammco machines

- On-site repair and calibration

- Test cuts performed after every service

- Fast scheduling for busy shops

- Coverage across Southern California